The Infrastructure Program’s Chain Reaction

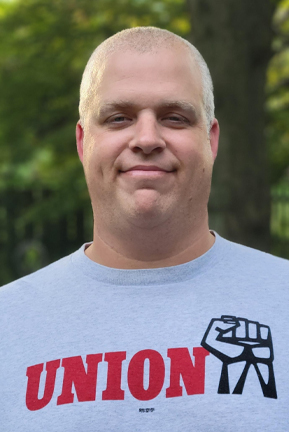

Chris Frydenger and his co-workers at the Mueller Co. in Decatur, Ill., began ramping up production of valves, couplings and other products used in water and gas systems soon after President Joe Biden signed the Infrastructure Investment and Jobs Act (IIJA) last year.

But the life-changing impact of the $1.2 trillion infrastructure program really struck Frydenger, grievance chair for United Steelworkers (USW) Local 7-838, when management reached out to the union with an unprecedented proposal.

The company asked to reopen the local’s contract and negotiate an additional pay increase so it could hire and retain enough workers to meet the dramatic spike in orders. “Everybody in the union got a raise,” Frydenger recalled.

Historic improvements to America’s roads, bridges, airports, public utilities and communications networks have generated surging demand for aluminum and steel as well as raw materials like nickel and ore and the pipes, batteries, valves and other components needed for thousands of infrastructure projects.

That demand, in turn, continues to create family-sustaining jobs, put more money in workers’ pockets and lift the middle class, just as labor unions and their Democratic allies predicted when they pushed the legislation through Congress and onto Biden’s desk.

“This story needs to be told, for sure. It at least doubled our business in a short period of time,” said Frydenger, noting the local’s 408 members not only received middle-of-the-contract pay increases but continue to avail themselves of all the overtime they want.

Workers use that extra money to buy cars and appliances, remodel their houses and support local businesses, among many other purposes, helping to extend the IIJA’s reach to virtually every segment of the local economy.

“It’s had such an impact that in our new hire orientations, our general manager talks about it,” Frydenger said of the IIJA. “That’s how big an impact it’s had on sales. He gives all the credit to the infrastructure bill.”

The billions allocated for drinking water, sewer and stormwater upgrades will enable utilities across the nation to extend distribution systems, replace aging pipes, curtail runoff and address lead and other contaminants. And investments in natural gas infrastructure—as well as solar, wind and hydrogen power—will help the country build a more secure, reliable energy base.

Domestic procurement requirements in the infrastructure law will ensure these projects rely on products such as those made at the Decatur plant. What makes Frydenger happier still is knowing that his union brothers and sisters up and down the supply chain also have brighter futures because of the infrastructure push.

An increasing number of orders prompted Mueller Co. to expand its purchases of brass, a raw material in the company’s production process. Helping to fill that need are about 225 members of USW Local 7248 at Wieland Chase, a brass manufacturing plant in Montpelier, Ohio, and about 50 members of USW Local 9777 at H. Kramer & Co., a brass and bronze ingot foundry in Chicago.

An increasing number of orders prompted Mueller Co. to expand its purchases of brass, a raw material in the company’s production process. Helping to fill that need are about 225 members of USW Local 7248 at Wieland Chase, a brass manufacturing plant in Montpelier, Ohio, and about 50 members of USW Local 9777 at H. Kramer & Co., a brass and bronze ingot foundry in Chicago.

“The orders have just piled up because of the rebuilding and construction,” said Local 9777 President Steve Kramer, noting that the business boom spurred by the infrastructure program helped his members win good raises and other gains in a recently completed contract with the foundry. “When orders are up and they’re under the gun, we’ve got a little more leverage.”

“They’re growing. They just hired more people,” Kramer said of the foundry’s increased business with Mueller Co., among other customers. He added that the IIJA also has boosted production and employment at many of the 40 or so other USW-represented companies covered by his amalgamated local.

The Decatur plant sells products directly to customers. But it also ships some of what Frydenger and his co-workers make to other Mueller facilities, where even more USW members are experiencing the benefits of the infrastructure program.

“It just flooded our orders,” said Chad Dickerson, president of Local 00065B, which represents about 450 union members who manufacture Mueller fire hydrants in Albertville, Ala., known as the “fire hydrant capital of the world.”

“It’s definitely created some jobs for us,” said Dickerson, adding, “We’re going to start staffing a weekend crew.”

The increase in orders “probably added 50 jobs we never would have had,” and Dickerson estimated the need to create up to 100 more jobs in coming months.

Those hydrants go to places like Groton, Conn., where members of USW Local 9411-00 provide water and sewer service to thousands of customers.

“The Mueller hydrant is our standard throughout the system,” explained Kevin Ziolkovski, Local 9411-00 unit president, whose members at Groton Utilities serve the city of Groton and a handful of neighboring communities.

Crews installed some of the hydrants in a housing plan during a recent maintenance program, he said, calling them “easy to work on” and “tough as steel.” He added that even after they’re struck by vehicles, an occasional occurrence, USW members need only “change a few parts and put them back in service.”

Ziolkovski and his co-workers look forward to using more of those hydrants and other Mueller products in infrastructure program projects that would boost customers’ safety and quality of life.

Ziolkovski and his co-workers look forward to using more of those hydrants and other Mueller products in infrastructure program projects that would boost customers’ safety and quality of life.

“Any time you upgrade the system, you reduce the possibility of water main breaks or blockages,” Ziolkovski observed. “Your water quality increases. Your water pressure is better.”

Workers at Mueller have been making these top-of-the-line products for about 150 years. With the infrastructure program, Frydenger noted, they’ll continue making them—and newer versions—for decades to come.

“We’re innovating more every day,” he said. “I can’t tell you how much it fills my heart to be part of this.”

*

Photos of Chris Frydenger, of fire hydrants made by USW members and of a hydrant stamped Albertville, Ala., where it was manufactured by members of USW Local 00065B.

By clicking Sign Up you're confirming that you agree with our Terms and Conditions.

Related Blogs

Ready to make a difference?

Are you and your coworkers ready to negotiate together for bigger paychecks, stronger benefits and better lives?