BASF Locals Discuss Plant Issues at Annual Council Meeting

This article originally appeared in Chemical Solutions, Issue 13.

BASF locals shared information, strategies and solidarity at their annual council meeting Aug. 1-2 in Geismer, La. Local 13-620 represents the workers at BASF’s Geismer plant and Unit Chair Doug Watts hosted the meeting.

District 13 Director Daniel Flippo, who has headed the BASF council since its inception in 2005-2006, opened the meeting by discussing the council’s importance.

“This council is crucial because it allows BASF local unions to share their collective knowledge and resources. This communication and solidarity prevents BASF from pitting locals against each other, and council activity forces the company to take its workers seriously,” Flippo said.

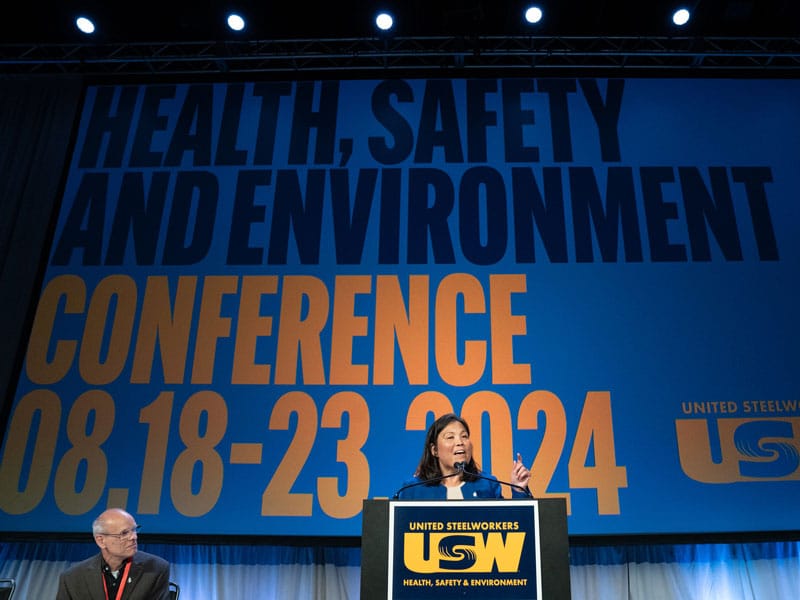

International Vice President Carol Landry, who heads the USW’s chemical sector, spoke on the need to organize the chemical industry, especially since chemical companies are consolidating their economic power through merger and acquisition.

“As companies continue to consolidate economic power, we, too, must increase our membership so that workers have a voice and are able to set standards across an industry that is often dangerous and volatile,” Landry said. “Our chemical councils are essential to this process, and can help with organizing drives.”

Health & Safety

Local 13-620 discussed the peer-to-peer safety observation process used at the Geismer facility. They said the workers control this behavior-based safety program, and that it goes beyond worker observation to include what is happening in a worker’s environment.

Workers are graded on 35 critical behaviors, and distinction is made between member and contractor observations. Unlike member observations, contractor observations are subject to a quota.

This is an entirely different health and safety program from the USW’s Triangle of Prevention program (TOP). TOP goes beyond behavioral-safety to also focus on the Systems of Safety—design and engineering, mitigation devices, maintenance and inspection, warning devices, training, procedures and personal protective equipment. Workers and management jointly investigate near misses and incidents, track them and pass on what is learned so an incident does not happen again.

Staffing Levels

At the time of the council meeting, Local 10-74 from BASF’s Monaca, Pa., plant was concerned about the company’s refusal to fill the relief operator position and its desire to eliminate it. Without enough operators, work is not getting done.

Health and safety incidents are more likely to happen when there are not enough people to do the work, especially in a dangerous environment like a chemical plant.

When management fills the position with excessive overtime, it can cause worker fatigue, leading to employee mistakes that cause incidents and near misses.

Local 10-74’s contract expires in February 2019, and the local underwent Building Power training in September to prepare for bargaining.

Issues to Tackle

BASF facilities in McIntyre and Oconee, Ga., are next to one another. Local 9-237 (McIntyre) and Local 9-237-01 (Oconee) said both sites have new managers.

They said management conducted searches using dogs and fired employees with 15 years of service. One employee received a warning for having a beer can in a car trunk.

Local 9-233 from BASF’s Gordon, Ga., plant said it has four outstanding grievances involving terminated workers who have 20 or more years of service.

All three locals are having problems with the company not allowing employees on disability—who have received a doctor’s clearance—to return to work.

Another issue is BASF’s desire to contract out full-time employees’ work.

Contract Settlements

Local 170-01 signed a five-year contract in November 2017 with BASF at its Attapulgus, Ga., plant. Six months later, the local gained five new members.

Local 174 at the BASF Quincy, Fla., facility signed a five-year contract last summer that included an increase in the company’s contribution to the 401k plan from 1 percent to 3 percent. Workers also received an increase in bereavement leave from three to five days. The local also won the right to determine which of the seven to eight temporary workers would get hired.

Local 13-620 members at the Geismar plant ratified a five-year agreement on Aug. 29 that included needed changes to the bid language, wage increases and more flexibility for the local to address issues on the shop floor.

The local successfully thwarted the company’s original proposal to curtail bidding and seniority rights so it could reduce employee movement and restructure the plant. Instead, the local proposed a reorganization plan that met BASF’s concerns and did not radically restrict workers’ rights.

Watts credited the solidarity of the council for his local’s success.

“Because of the BASF council and the annual meeting at our plant, our negotiating committee went to the table with the confidence of knowing they were not alone,” Watts said.

By clicking Sign Up you're confirming that you agree with our Terms and Conditions.

Recent News Articles

Want to Learn More?

See how the USW is making a real difference in our communities and our workplaces.